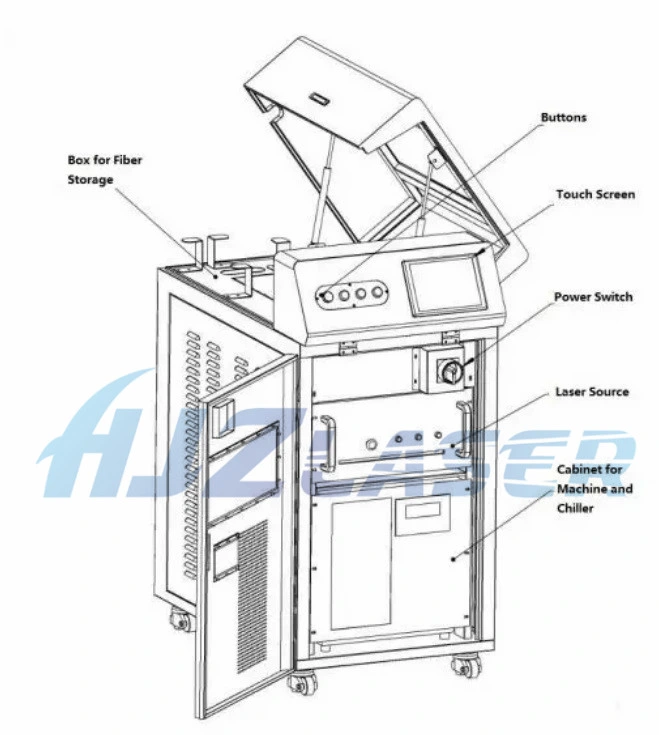

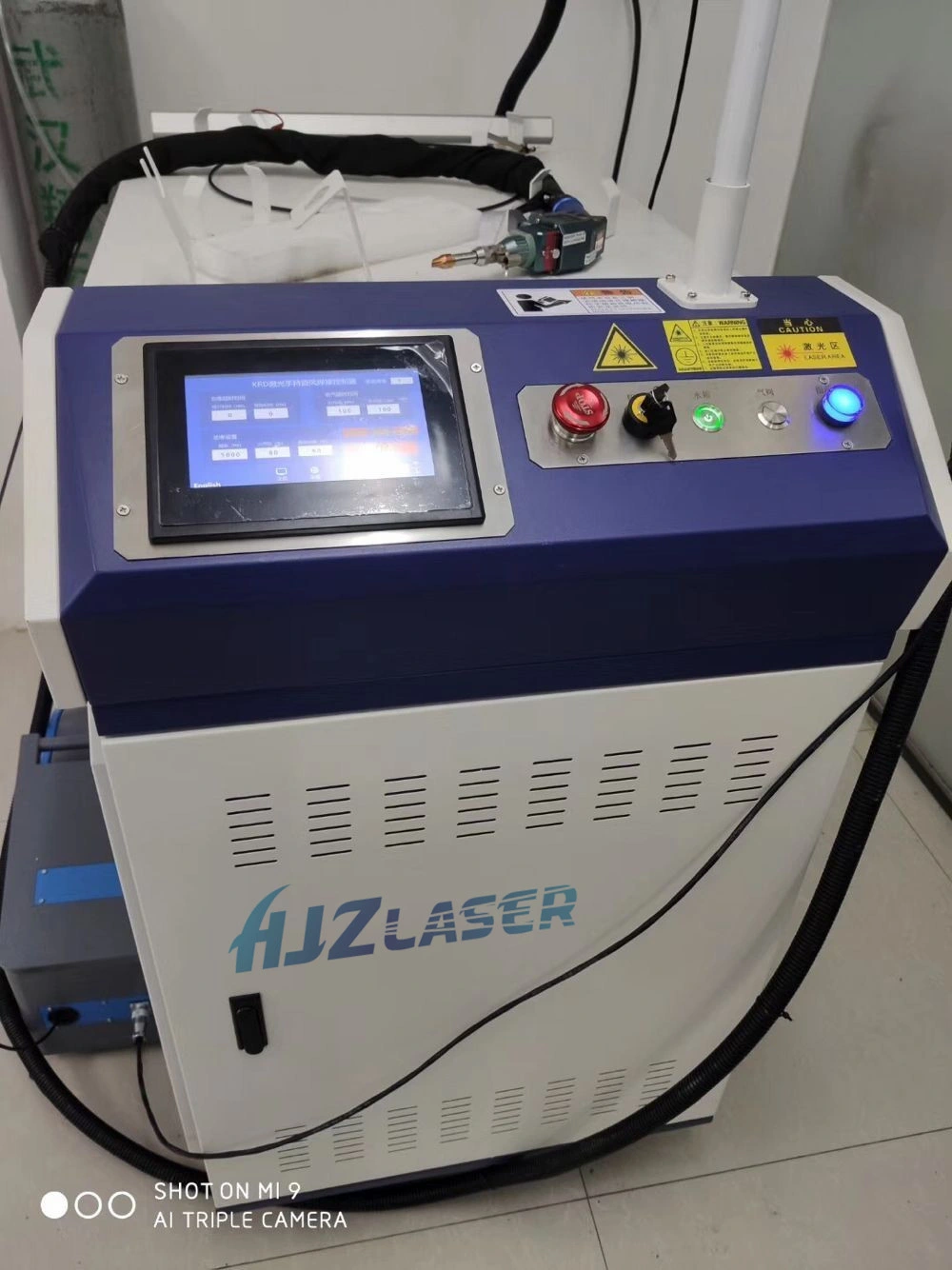

500W 1000w Handheld Stainless Steel Laser Welding Machine For Sale

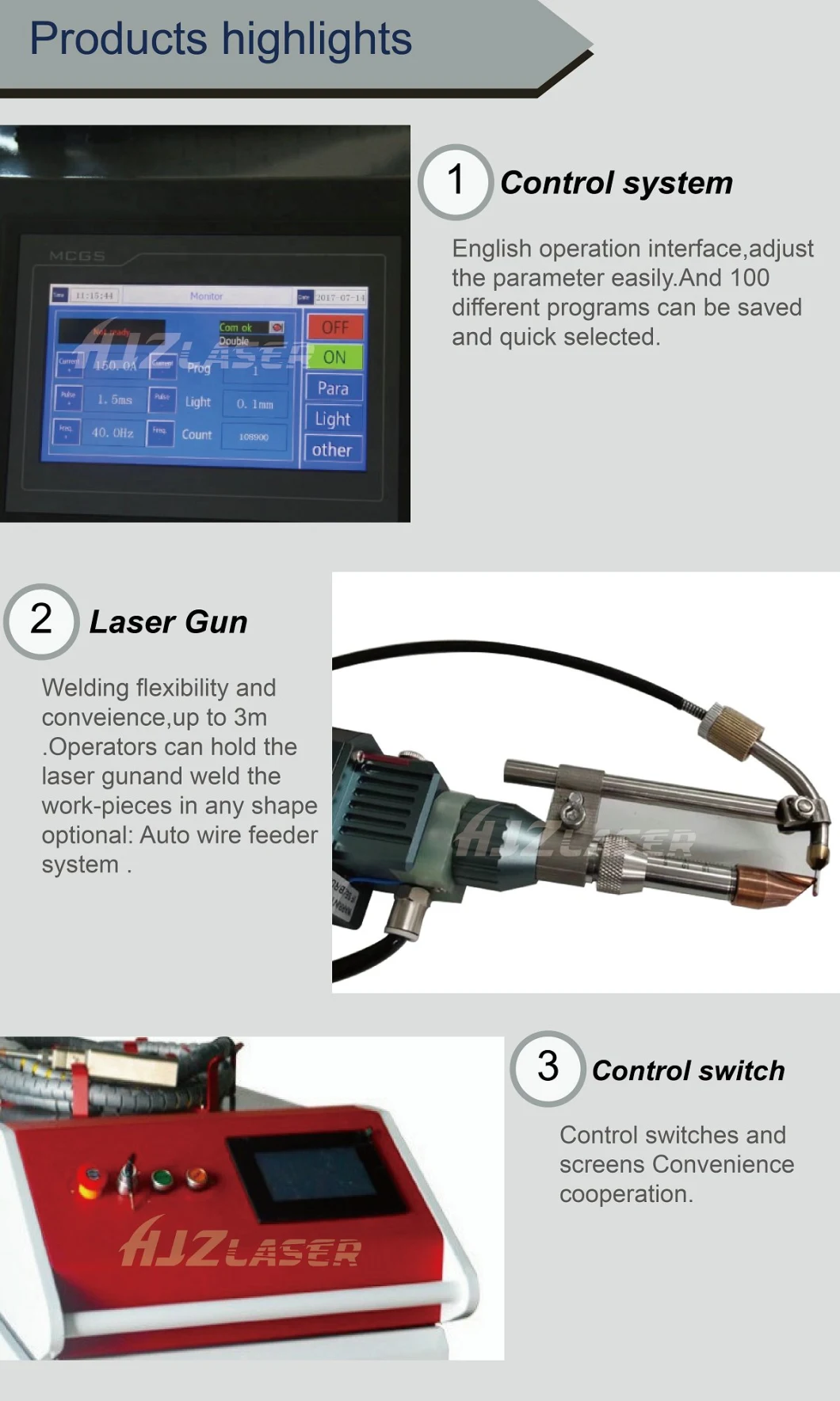

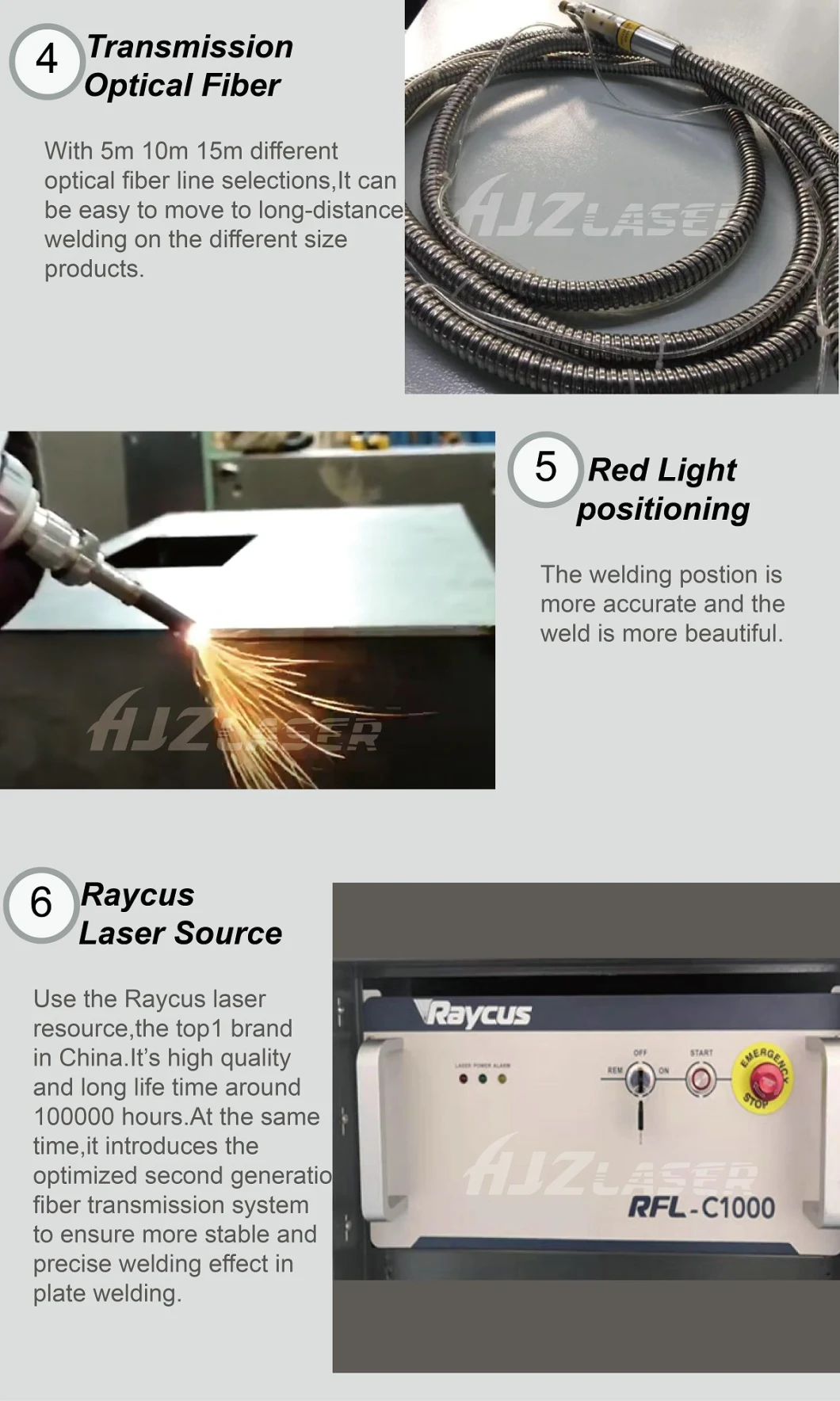

hand-held laser welding machine consists of the latest generation of fiber laser generator, wobble welding head and cabinet.

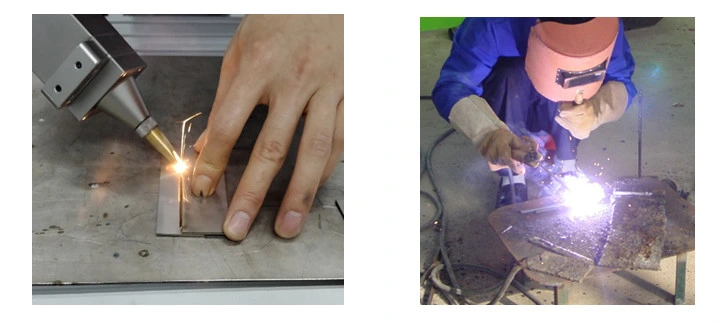

1.With simple operation, beautiful and smooth weld seam effect, fast welding

speed and no consumables needed during welding process.

2. Welding in thin metal plates such as stainless steel plates, iron plates and galvanized

plates can perfectly replace traditional argon arc welding and electric welding.

Product Picture

1. The weld seam is smooth and beautiful. The welded workpiece has no deformation, no welding scar,

and the welding is firm, which reduces the subsequent polishing, grinding process, and save time and cost.

2. Simple training, and operation. Beautiful products can be welded without the professional teacher guide.

Product Advantages

1. Independently developed wobble welding head is with swing welding mode, adjustable spot width, and strong welding fault tolerance. It expands the tolerance range of machining parts and weld seam width, and obtain better weld formation

2. Fast welding speed, 2-10 times faster than traditional welding.One unit of laser welding machine can replace at least two workers yearly.

Laser welding seldom needs consumables. It is with long life span, safer and more environmentally friendly.

Advantage Comparison

| Comparison process | Tradition Welding | Fiber Laser Welding | Our HJZ Laser Welding |

| Heat input to the workpiece | Very High | Low | Low |

| Deformation of the workpiece, undercut | Big | Small | Small |

| Bond strength to base metal | General | Good | Very Good |

| Follow-up | Polish | No polish, or rarely polish | No polish, or rarely polish |

| Weld Speed | General | More than 2 times argon arc welding | More than 2 times argon arc welding |

| Applicable Material | Stainless steel ,Carbon steel, Galvanized sheet | Stainless steel, Carbon steel, Galvanized sheet | Stainless steel, Carbon steel, Galvanized sheet |

| Consumables | Need more consumables | Seldom need consumables | Seldom need consumables |

| Operation | complex | Normal | Simple |

| Operator safety | Unsafe | Safe | Safe |

| Environment protection | Not environmentally friendly | Environmentally friendly | Environmentally friendly |

| Welding fault tolerance | Excellence | Not good | Excellence |

| Wobble welding | No | No | Yes |

| Spot width adjustable | No | No | Yes |

| Welding quality comparison | Worse | Normal | Very Good |

Performance and Technical Parameters

1. Technical Parameters

| Serial No. | Specification Detail | Parameters |

| 1 | Device Name | Hand held fiber laser welding machine |

| 2 | Laser Power | 500W,800W,1000W,2000W,3000W |

| 3 | Laser Wavelength | 1070 NM |

| 4 | Fiber Length | Standard length: 10M Longest length(support): 15M |

| 5 | Working Mode | Continuous / Modulation |

| 6 | Welding Speed Range | 0~120 mm/s |

| 7 | Water Chiller | Industrial thermostatic water tank |

| 8 | Working Environment Temperature | 15~35 ºC |

| 9 | Working Environment Humidity | < 70% No condensation |

| 10 | Welding Thickness Eecommendations | 0.5-3mm |

| 11 | Welding gap requirements | ≤0.5mm |

| 12 | Operating Voltage | AC 220V |

2.Welding penetration Melt depth data (wobble welding head):

Industry application

The hand-held laser welding machine can be widely used in complex and irregular welding processes in cabinet, kitchen and toilet supplies, stairs, elevators, shelves, ovens, stainless steel doors, and windows, guardrails, electric cabinet, stainless steel furniture and other industries.

Packing Detail

Why choose us

A. More than 10 years laser marking, welding, cleaning, processing, manufacturing, research and design rich experience.

B. Professional technical group for customized industrial laser marking system.

C. More than 3000+marking solution cases accumulated in domestic and oversea markets.

D. 100% strict QC for both raw materials and finished products.

E. Utility Model Patent Certificates,Nameplate Auto marking ,Engine cylinder block and head pass-type auto marking,

Automobile forged wheel hubs pass-type auto marking, copyright of computer software,etc.

F. ISO,CE,SGS certified and complete aftersales service team.

FAQ

Q1: What type of the machine suitable for us?

Please tell us what products, material, size, thickness will be welded , we will advise you the suitable model machines. If you can provide products picture, it is better.

Q2: If we do not know how to use the machine,can you teach us?

Yes, we will. Our user manuals are together with goods shipment. We can also send operation video to you for study.

If you come to our factory in China, our technicians will offer you free training until you can use machine freely.

Our professional engineer can come to your country for trainning, installation, adjusting, ect.

Q3: How about the delivery time?

For standard machine, lead time is 10-15 days.

Regarding customized machine, we need to check with technicians.

Q4: How about the warranty time?

Our laser welding machine warranty time is 12 months. Please send back the broken parts to us, we will send the new and replaced one to you. We suggest you take one extra set of spare parts together with your order which will be more convinient for your production line continurous running.

Please tell us what products, material, size, thickness will be welded , we will advise you the suitable model machines. If you can provide products picture, it is better.

Q2: If we do not know how to use the machine,can you teach us?

Yes, we will. Our user manuals are together with goods shipment. We can also send operation video to you for study.

If you come to our factory in China, our technicians will offer you free training until you can use machine freely.

Our professional engineer can come to your country for trainning, installation, adjusting, ect.

Q3: How about the delivery time?

For standard machine, lead time is 10-15 days.

Regarding customized machine, we need to check with technicians.

Q4: How about the warranty time?

Our laser welding machine warranty time is 12 months. Please send back the broken parts to us, we will send the new and replaced one to you. We suggest you take one extra set of spare parts together with your order which will be more convinient for your production line continurous running.

Contact Us: