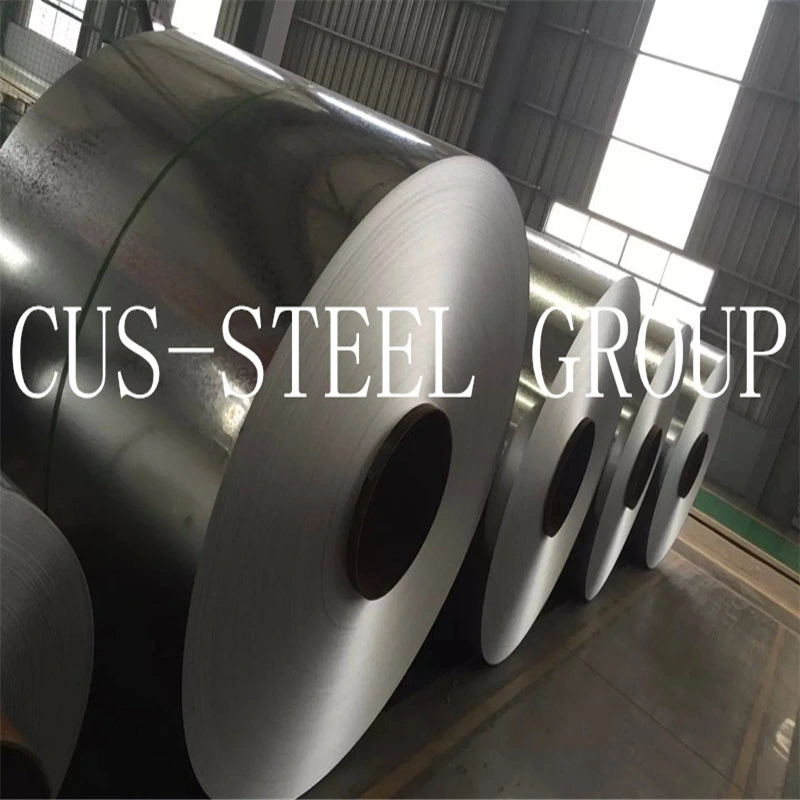

1. Hot DIP Galvanized Steel Coil Description

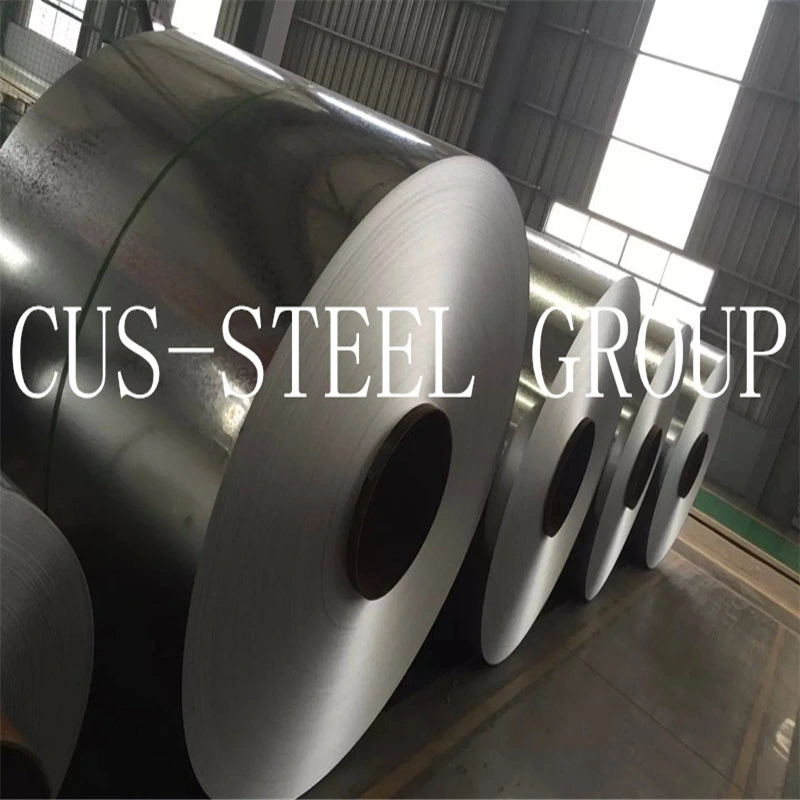

Hot dipped galvanized steel is typically a multiple step process that requires a metal workpiece to

be fluxed in molten or aqueous zinc ammonium chloride before a layer of zinc is bonded to it. The

pure zinc layer then turns into zinc oxide when it is exposed to oxygen, and finally zinc carbonate

after exposure to carbon dioxide

2. Hot DIP Galvanized Steel Coil Process

1)After cleaning and acid pickling, the steel coil is submerged in melted zinc, a chemical reaction

permanently bonds the zinc.The zinc actually permanently becomes a part of it and successive

2)Layers are a mixture of zinc and iron. Hot dipped galvanized steel is a special type of steel coil

used in a number of different applications within fabrication and manufacturing environments

3. Hot DIP Galvanized Steel Coil Flow Chart

Decoiler--- Shearer ----welder ----pre-treatment ----entry looper--- annealing furnace--- zinc pot

---- air cooling tower ----water cooler--- leveller---- post treatment ---exit looper crimper

4. Hot DIP Galvanized Steel Coil Advantages

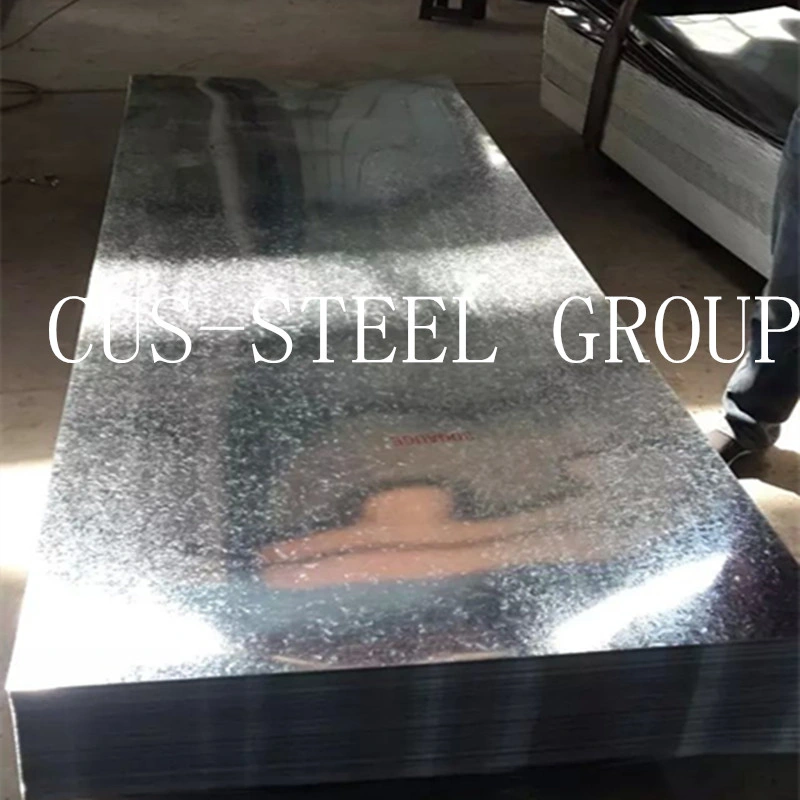

1)Low iron loss, high magnetic flux strength, comes up to the international advance standard

2)Slight thickness difference between the horizontal and the longitudinal direction, promising high

lamination factor

3)Processing Performance: Easily punched and cut, high dimensional accuracy

4)Insulating coating: Uniform color, good insulation, strong adhesively, high heat resistance, high imputrescibility

5)Smooth surface,no rust,no rolling marks,no cold lap,no crease,no bubble cell

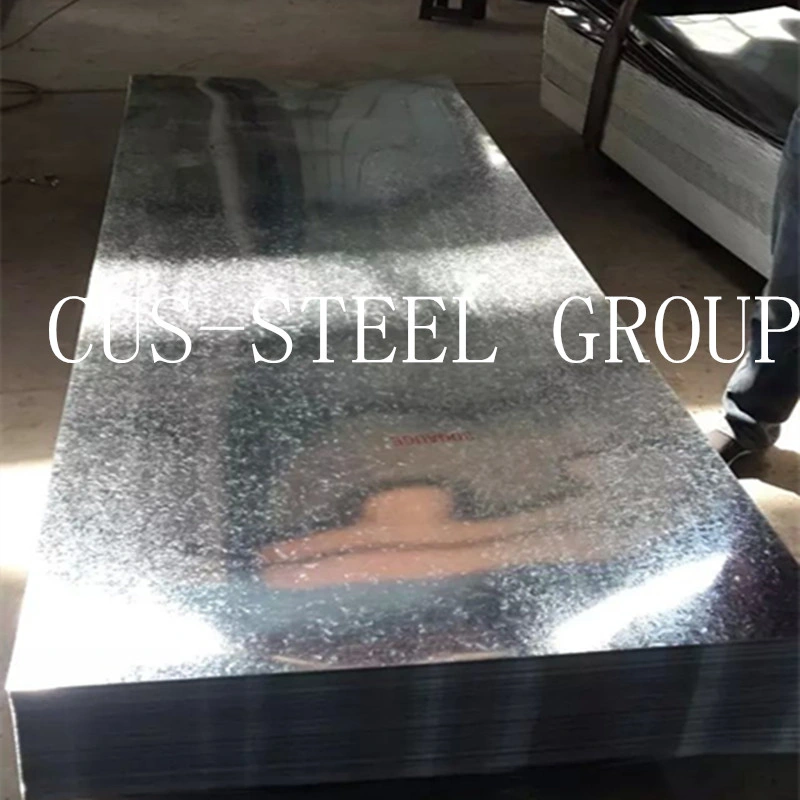

5. Hot DIP Galvanized Steel Coil Usage Scope

1) Outdoor application:

Roof, structural balcony, panels, window sills, window frames, gates, garage doors, rolling doors,

booths, shutters, watc rooms, makeshift houses, street waiting room (booth), refrigerators, etc

2) Indoor application

Room doors, dividing walls, door frames, light house steel structures, sliding doors, screens,

ceilings, toilets, interior elevato lobby, stairwayventilating duct, communication pipelines

Hot dipped galvanized steel is typically a multiple step process that requires a metal workpiece to

be fluxed in molten or aqueous zinc ammonium chloride before a layer of zinc is bonded to it. The

pure zinc layer then turns into zinc oxide when it is exposed to oxygen, and finally zinc carbonate

after exposure to carbon dioxide

2. Hot DIP Galvanized Steel Coil Process

1)After cleaning and acid pickling, the steel coil is submerged in melted zinc, a chemical reaction

permanently bonds the zinc.The zinc actually permanently becomes a part of it and successive

2)Layers are a mixture of zinc and iron. Hot dipped galvanized steel is a special type of steel coil

used in a number of different applications within fabrication and manufacturing environments

3. Hot DIP Galvanized Steel Coil Flow Chart

Decoiler--- Shearer ----welder ----pre-treatment ----entry looper--- annealing furnace--- zinc pot

---- air cooling tower ----water cooler--- leveller---- post treatment ---exit looper crimper

4. Hot DIP Galvanized Steel Coil Advantages

1)Low iron loss, high magnetic flux strength, comes up to the international advance standard

2)Slight thickness difference between the horizontal and the longitudinal direction, promising high

lamination factor

3)Processing Performance: Easily punched and cut, high dimensional accuracy

4)Insulating coating: Uniform color, good insulation, strong adhesively, high heat resistance, high imputrescibility

5)Smooth surface,no rust,no rolling marks,no cold lap,no crease,no bubble cell

5. Hot DIP Galvanized Steel Coil Usage Scope

1) Outdoor application:

Roof, structural balcony, panels, window sills, window frames, gates, garage doors, rolling doors,

booths, shutters, watc rooms, makeshift houses, street waiting room (booth), refrigerators, etc

2) Indoor application

Room doors, dividing walls, door frames, light house steel structures, sliding doors, screens,

ceilings, toilets, interior elevato lobby, stairwayventilating duct, communication pipelines

| Standard | Steel Grades | Application |

| GB/T 2518-2004 | 01 | Common commercial application |

| 02 | For mechanical engagement | |

| 03 | For stamping | |

| 04 | For deep drawing | |

| 220,250,280,320,350 | For structural components | |

| JIS G 3302-1998 | SGCC | Common application |

| SGCD1 | For stamping | |

| SGCD2 | For deep drawing | |

| DIN EN 10142-2000 | DX51D+Z | For common application and mechanical engagement |

| DX52D+Z | For stamping | |

| DX53D+Z | For deep drawing | |

| DIN EN 10147-2000 | S220GD+Z | For structural components |

| S250GD+Z | ||

| S280GD+Z | ||

| S320GD+Z | ||

| S350GD+Z |